Custom Solutions

Diverse Machining Capabilities from Prototype to Production

With over 40 years of experience, Bears Performance delivers precision machining through multi-axis CNC, advanced lathes, milling, and fabrication services—tailored to a wide range of project needs.

Our versatile capabilities allow us to produce high-precision components for even the most complex and demanding applications, ensuring exceptional accuracy and reliability.

Precision Machining Service

CNC Turning

Bears Performance delivers high-quality CNC turning services for producing precision parts with exceptional accuracy. Our advanced process enables fast turnaround on custom prototypes and end-use production components.

CNC Milling

Bears Performance has invested a great deal in new machinery, enabling us to offer 2, 3, 4, and 5 axis CNC milling. We regularly undertake complex precision CNC machining services for both the automotive and non-automotive industries.

Wire EDM

Our Wire EDM services produce extremely accurate components made of hardened steels, exotic metals, brass, carbide, aluminum, and graphite. We have the capacity to handle a variety of your production needs from prototype to short, medium or long run production.

Prototype Machining

Bears Performance is staffed and equipped to produce a dimensionally precise prototype of virtually any part and quantity, including complex parts – with the highest possible accuracy. Our engineers and machinists work with a wide variety of materials, including stainless steel, aluminum, etc.

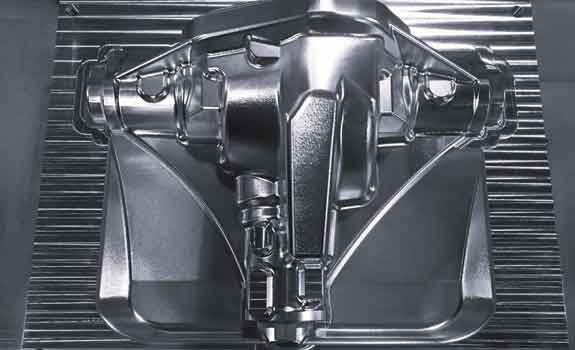

Mold Making

Bears Performance has over 4 decades of expertise in mold making, injection and compression molding, as well as castings for plastic and rubber injection. Our capabilities include creating complex molds for rubber compression, aluminum, and cast iron castings.

Custom Tig and Production Mig Welding

Bears Performance is more than just a machining company. While our highly trained team are excellent machinists, we also provide a wide range of added value tasks such fabricating, bending, welding, deburring, dimensional inspection and more.